Commercial aviation has become a fundamental pillar of the global economy today, it allows us to swiftly transport goods and people all around the world, facilitating over a third of the world’s total trade value and supporting more than 87 million jobs worldwide.

However, the aviation sector is responsible for around 2.5% of carbon dioxide emissions contributing to global warming and about 5% of human-induced climate change, numerous efforts have been made to reduce this impact over time, but the transformation in this sector is happening at a very slow pace.

The basic design of commercial aircraft hasn’t changed significantly in the past sixty years, modern airplanes like the Boeing 787 and Airbus A350 still share a similar overall shape to aircraft like the Boeing 707 and Douglas DC-8, which were built in the late 1950s, they feature the characteristic “tube and wing” design that is still in use today.

This is because commercial aviation prioritizes safety and favors tried-and-tested solutions, other advancements, like materials and engines, have evolved, but the traditional design remains suitable.

Given that the aviation industry is making every effort to reduce carbon emissions, it faces a greater challenge than other sectors due to the complexity of transforming its core technologies, therefore, it’s time to explore something new.

What is the proposed new design for commercial aircraft?

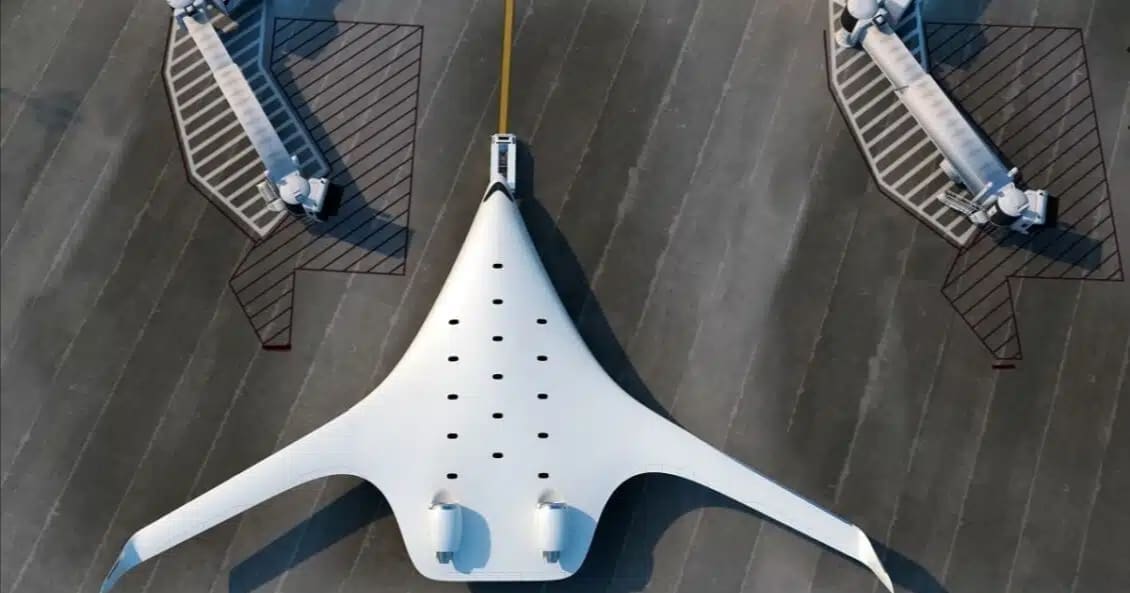

There have been numerous proposals to decrease fuel consumption and carbon footprint of commercial aircraft, one such proposal is the “Blended Wing Body” (BWB) design, unlike the traditional tube and wing design, the Blended Wing Body design doesn’t have a clear separation between wings and the fuselage, often resulting in an aircraft without a distinct tail.

The new design appears quite similar to the concept of a “flying wing” used in military aircraft like the B-2 bomber, however, the Blended Wing Body design typically has a larger midsection.

Both Boeing and Airbus are working on modifying the concept, a new company called JetZero, based in California, has also emerged, it has set an ambitious goal to have a blended wing aircraft in operation by 2030.

Tom O’Leary, co-founder and CEO of JetZero, stated to CNN, “We feel that there needs to be a pathway to zero emissions for large aircraft, and the blended wing design will contribute to a 50% reduction in fuel burn and emissions, which is a remarkable leap forward compared to what the aviation industry is used to.”

Advantages of the blended wing design in aircraft include fuel efficiency and a larger payload capacity in the middle section of the aircraft, this concept isn’t entirely new, with prototypes being developed for decades, NASA, for instance, tested it with their experimental X-48 aircraft.

Through nearly 120 test flights conducted between 2007 and 2012, two X-48 model remote-controlled drones proved the viability of the blended wing design, NASA stated that an aircraft of this type would have a slightly larger wingspan than a Boeing 747 and could operate from current airport terminals, furthermore, the aircraft would be lighter in weight, generate less noise and emissions, and have lower operating costs compared to advanced conventional aircraft.

The new design offers increased fuel efficiency, larger payloads, the ability to use shorter runways, and reduced operational costs.

In 2020, Airbus introduced a small remotely controlled aircraft model, showcasing its interest in the design at the Singapore Airshow 2020, this suggests the potential for full-scale future applications.

So, if this design is so effective, why haven’t companies used it in aircraft design so far?

According to Tom O’Leary, there’s a major technological challenge hindering manufacturers from adopting the blended wing design in their aircraft, this challenge arises from the pressure exerted on the aircraft’s body due to its non-cylindrical design, he mentioned that cylindrical aircraft designs are better equipped to handle the continuous expansion and contraction cycles that come with each flight.

He further explained that while the traditional tube and wing design separates loads, distributing pressure loads on the fuselage and bending loads on the wings, the blended wing design mixes these loads, only with the use of lightweight and strong composite materials is it now possible to implement this design.

This new design could lead to a completely different interior layout compared to existing aircraft, O’Leary stated, “This new design will allow for larger interior spaces, current single-aisle aircraft have three seats per row, but the new design is a shorter and wider tube that can carry the same number of people, but you might have 15 or 20 rows depending on how each airline executes the design.”

The Revolutionary Potential and the U.S. Military:

Bailey Miles, an aviation analyst at AviationValues consultancy, noted that while the blended wing design shows promise, the actual benefits depend on design specifics and operational conditions, NASA and Airbus announced more modest efficiency gains of around 20%, while the U.S, Air Force stated a potential 30% improvement in aerodynamic efficiency compared to current military and transport aircraft.

Miles emphasized the necessity of extensive aerodynamic efficiency tests to realize the full potential of this innovative aircraft design, however, determining a specific percentage reduction in fuel consumption without these necessary tests is challenging.

The blended wing design is indeed a revolutionary concept with potential, but it comes with obstacles, including increased aerodynamic complexity, challenging design and testing, regulatory and certification challenges, and a shape that might not suit current airport infrastructure.

Richard Aboulafia, an aviation analyst at Aerodynamic Advisory, expressed his optimism about the concept but raised concerns about JetZero’s status as primarily a design shop, he believes that the project could gain traction with help from contractors, stating, “There’s always room for anyone who genuinely wants to add value to the industry.”